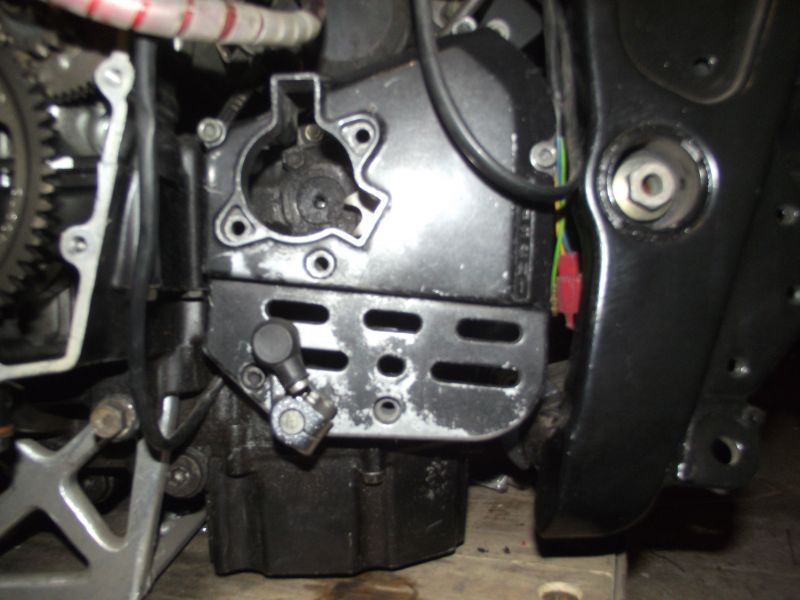

made the spacers for the oil blocks coz they were balked by the boot studs (i mean the steel part of the oil lines), powder coat them later

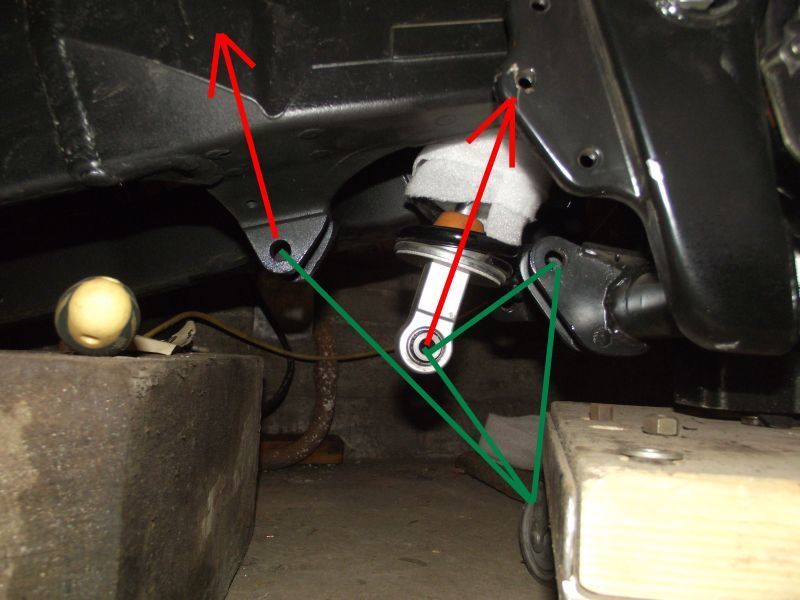

made an adjuster screw from a stock cable operated screw (the cable had burnt when occasionally touched the ground while welding went on

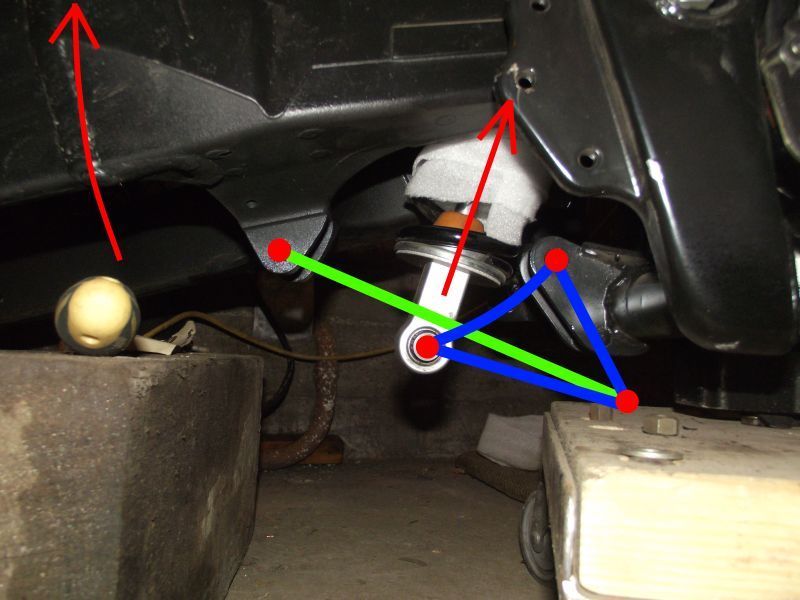

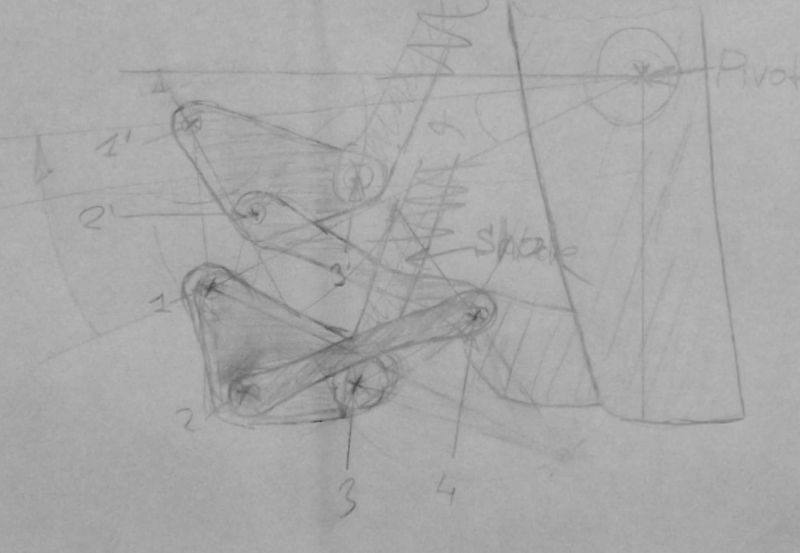

fabbing the cable ends

extentions powder coated

made inserts for them from an old cable sleeve, shove them in (hard way) using the vice and white spirit for lube, judged that if i'd used oil or wd40, would of been harder to degrease cables before soldering

soldered

now the cable saga/drama is over, just gunna lube em with trans oil

still gotta do lots of tiny dirty tricks like mounting the oil cooler, feeding and scavenging the turbo, wiring etc

Reply With Quote

Reply With Quote