hopefully it will Trev

hopefully it will Trev

Starting to look like the ASF logo frame - like it!

bahaha the image must of been imprinted in my head

Last edited by Surt; 16-03-2012 at 12:38 PM.

sooo yas liked the frame mates? coz i didn't! bwahahaha!

heres all the odds and bits i of cut of the frame so far, every little piece, theres nothing to cut of anymore haha

it would be alright with a standard carb setup but the side rails didnt let in tbp sensor and throttle cables pulley and brackets, which was noticed a tad to late

also theres to tight room in front for the ic and turbine set up

also the upper rails r too narrow and wouldnt let in busas turbo intake (and its rounded shape looks like an arse haha)

so ive finally took the resolution and cut the whole bloody frame apieces and started it anew

the invisible frame

so i decided to stretch it by moving the engine 100mm backwards also the steering neck's to be lowered by 40mm and the rear part of the frame is to be raised for 40mm so the frames gunna look flat as a bench; the rake is to be set at 28 deg

take a unique chance to look inside haha

another magick coincidence - the new tubes fit directly into the old ones tight as

the new begining

some more minor squirts

the lowered yoke was deprived of the stock damper mount and was tidied up a bit - mould seams ground of and smoothed

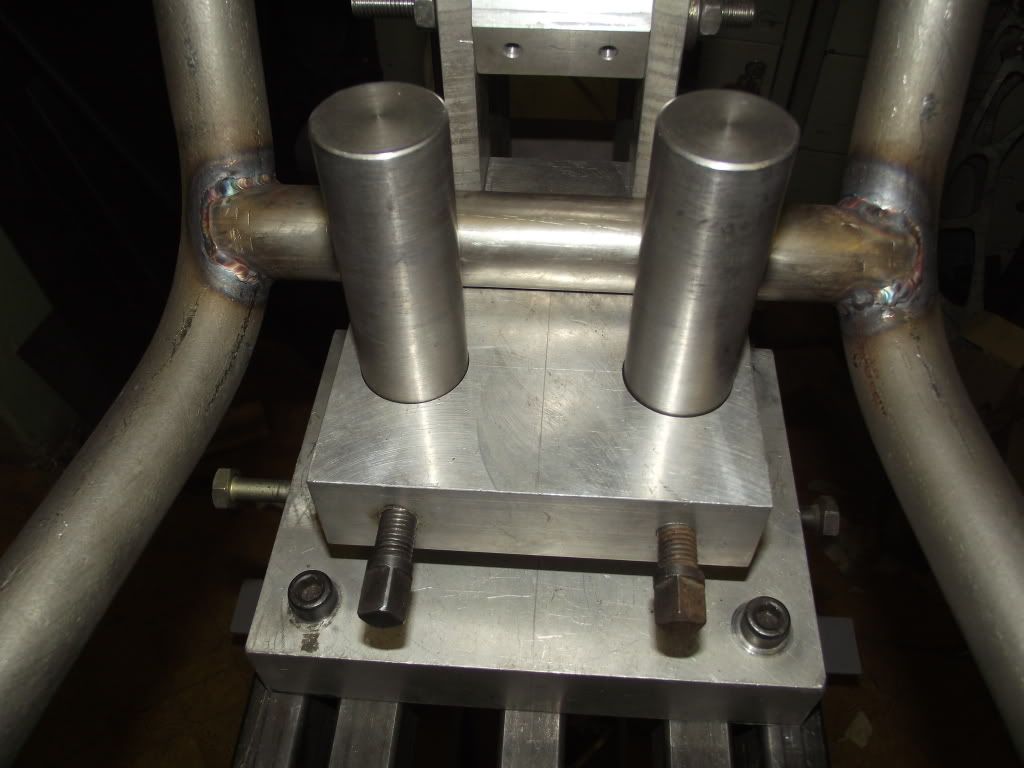

the new custom heat treated studs and nuts for engine mounts r gilded lol

the frames prepped for tomorrows welding

tacked and waitin for braces to be made

meterin whose bigger lol

Shit mate do you even sleep ????? Loving the progress.

thanks heaps Dan nah im in a state of astral most of the time haha!

the stacks for turbo plenum

spent helluva time trying to press out the lower bearing race, even drilled 2 holes to beat it out but it bloody stuck, the steering neck was deformed a bit in the bottom so i gave it to a turner to cut it of and to make a replacement which later was pressed on and welded around inside and outside, tomorrow its gotta be finally machined to the bearing race diametre

the cut off was cut off over again to release the race

the bracings have been welded to the upper tubes

ive used od34 x 1.5mm stainless piping, the same as for my willie bars, to save on weight

luv the seams! - not my cop naturally, a pros work but i did all preparations and governed the process as usual

now remembered a joke from a bike zine, germans from bmw manufactured tanks during the wwii so now when they try to make a car, they have a tank instead, when they wanted to build a bike, they r havin' a tank's comin' over again lol

same with me, i wanted a chopper but build a dragster, wanted a cafe racer but build a dragster, now a wanted just a tad fightered street bike girl friendly but bild a dragster all over and over again bahaha!

fitted the neck

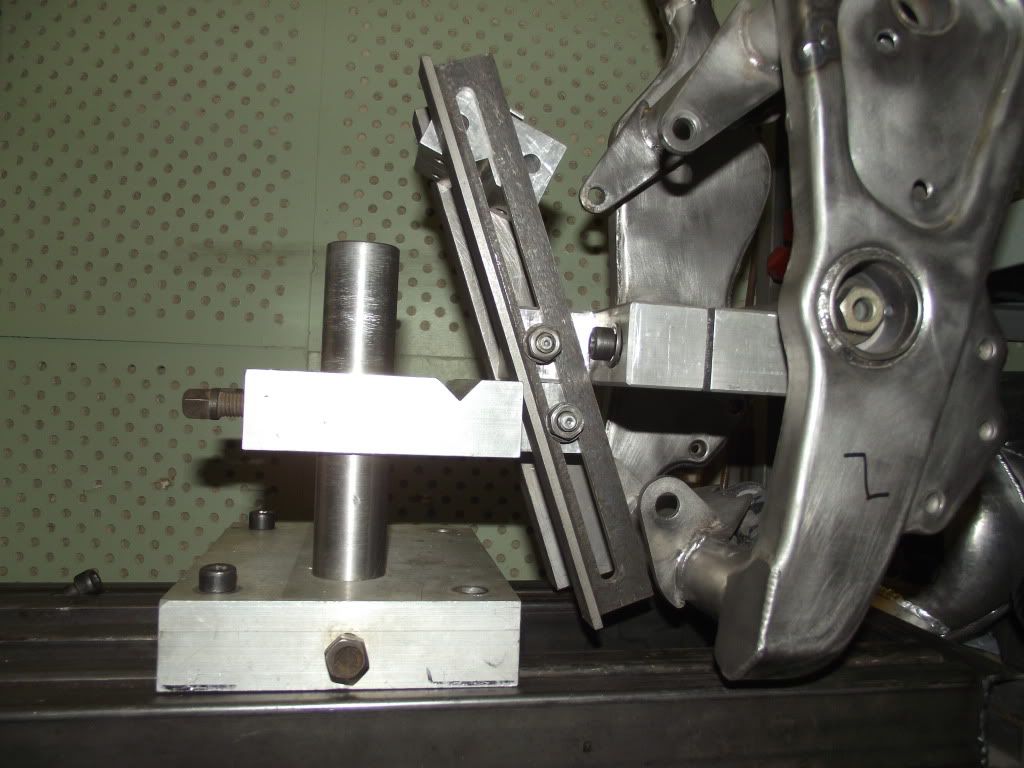

smart arse fixture for the pivot bolt

received the trigger wheel and vr sensor from triggerwheels.com now gotta save some coin for microsquirt ecu

opened up the right cover its pretty much fucked up in there, one of bolts beds is missing, gonna fugure out how to repair it

pressed the stem in

outta paint it tomorrow

heat treated ally bar stock for nuts

powder coated

had to cut of the steerin lock coz it didnt let to put the neck into lathe spindle to machine the hole for the lower bearing race, hopefully tomorrow the neck will be welded to the upper tubes