have been fairly quite in the bike building lately cause i have had my hands on a new project,

it is no bike but still costs heaps.

i decided after using my mill manually for a couple of years that cnc was the way forward. i did some research and took the plunge. i brought some 400 watt yaskawa AC servos motors and drives from ebay from a dude in korea that seems to have heaps of second hand cnc parts.

i then ordered some custom made pmi brand ground ball screws from tiawan.

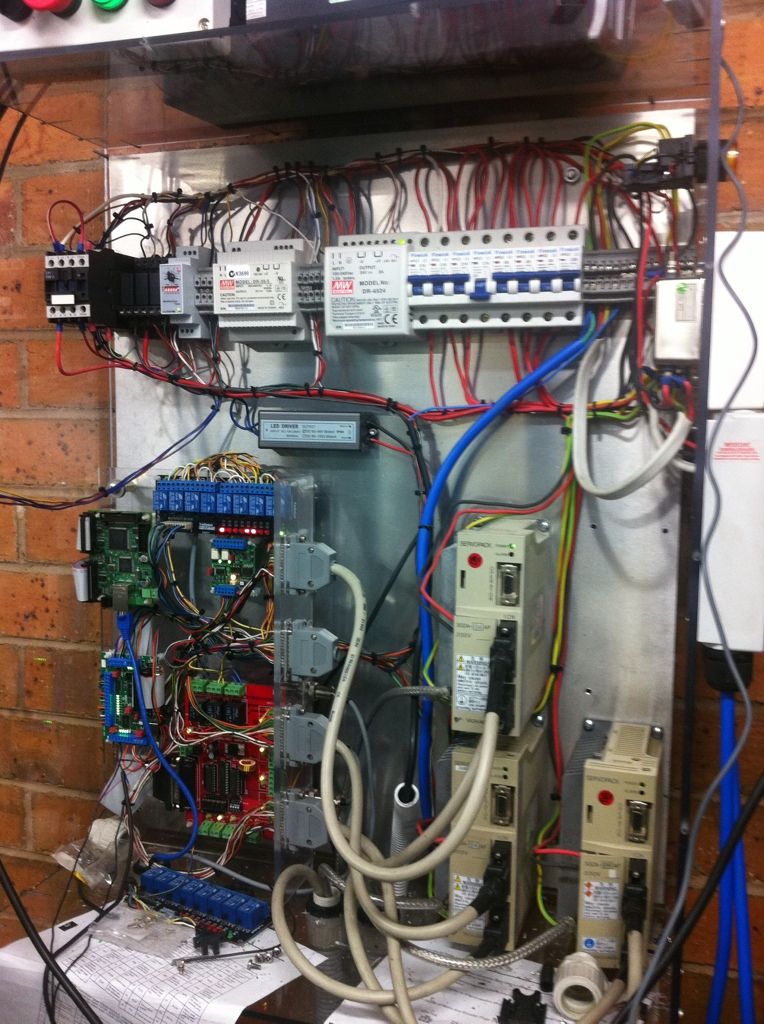

the biggest challenge so far has been the elect cab. so many circuits to think of and safety circuits as well.

the pc program controls the spindle rpm via a circuit board that controls the voltate to the invertor.

the coolant is switched by a relay once again controlled by an m code in the program

in the end it has all come together well.

i have alot more i want to do including

mount the 12v power supply to power the cooling fans so i can close the cab to protect from swarf

make some sort of guard for coolant and swarf. that shit goes everywhere.

higher pressure coolant (but not till the coolant guard is sorted)

ball screw guard for z axis<br>make a steel yoke to mount the z axis ball screw to the quill.

reinforce the z axis mount as the 12mm plate is prone to flex when taking heavy cuts

i have also ordered a pendant so i don't have to worry about being attached to the keyboard.

i have also designed a custom console. to make life easier.

i will post more progress as i get it done.

all up cost for the conversion at this stage would be about 5k.

since i have had it up and running i have picked up a good job that has already paid for the conversion and then some

one thing is that this is not a vmc. but it is also not a 100k machine and therefore doesn't perform like one.

for what i do it is good enough for now but in the future i can see a VMC for sure.

here is a vid of a braided hose clamp half being machined with a 14mm cutter and about 900mm a min.

Reply With Quote

Reply With Quote