-

Power Hungry, Law Disregarder

Dual light to single light

I have dual light high and low on my zed which I am swapping over to a 7 inch round light which only has one wire for low and one for high.

What I was wondering if I could find out what wire is the power for each and plug and fit spade onto new wire to get it working.

Sorry for basic description but I will try to explain better if needed.

The new light

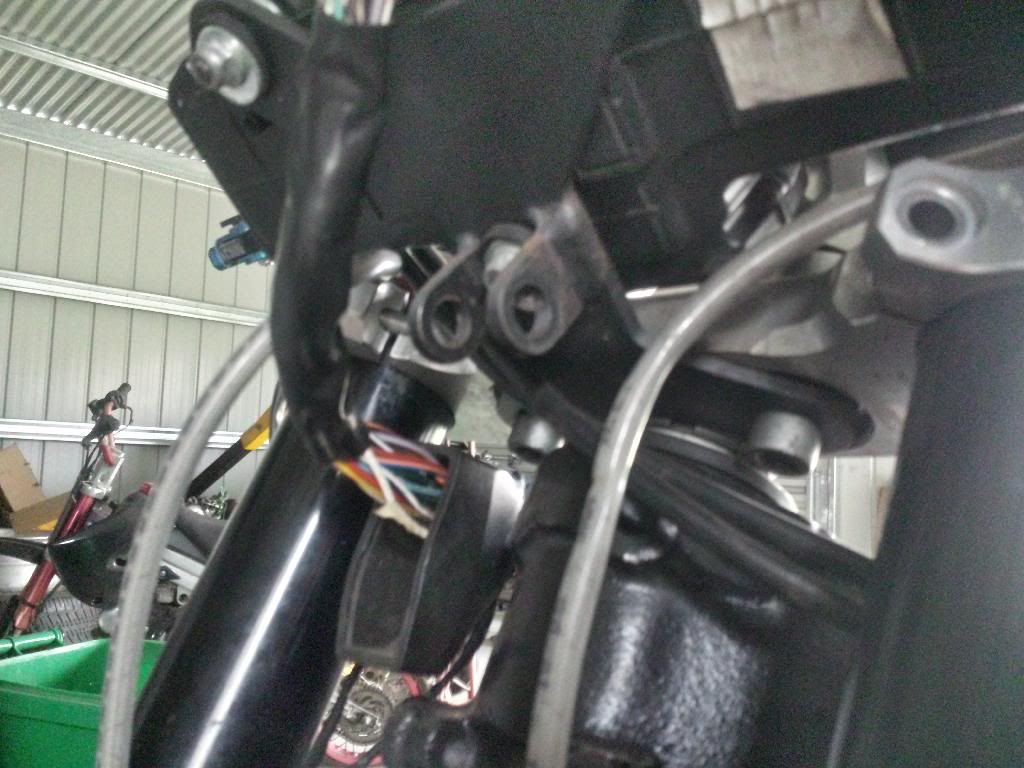

The factory fittings

The factory fittings

-

Tyre destroying, mad bastard menace

you could put male spades into the old globe fittings, however it would be a lot neater/more reliable if you just chopped off the factory fittings and soldered on the new one.

-

Power Hungry, Law Disregarder

Yer was thinking of that and I agree would be heaps neater.

Just need to design a bracket to suit now.

-

ASF Standard Full Member

If you look at the stock bulb it will show you which tab is earth as it will be connected to the outer of the bulb body the other two dont matter to much which way you put it around it is easy enough to swap if low = high etc.

-

Power Hungry, Law Disregarder

Thanks guys will try that and see how I go.

Does anyone have any ideas for a bracing as I've got a couple but I'm keen to see how everyone else has done it.

-

Tyre destroying, mad bastard menace

i like running mounts off the triple clamps to keep the forks clean, but that's just my style. it takes a little more effort too.

-

Power Hungry, Law Disregarder

Do have any pictures of what you are talking about.

-

Tyre destroying, mad bastard menace

I'll get some pictures of my mind this morning. Mine isn't a round light but it'll give you an idea.

-

Tyre destroying, mad bastard menace

-

Power Hungry, Law Disregarder

Thanks for that do you mind if use any of your ideas.

-

Tyre destroying, mad bastard menace

go for your life. there's no way it'll be exactly the same anyway. completely different bike and light. I'm pretty sure i wasn't the first person to mount a headlight off the triple clamps either.

-

Power Hungry, Law Disregarder

I was thinking about making top mount similar to the one you did where the gauges are on it.

This is what I have to work with.

And this is how I was thinking of mounting it to bike but not sure if might be to much vibration but with factory gauge.

-

Tyre destroying, mad bastard menace

you've got it pretty good with those hole on the front there, though i reckon you're right and that mounting system would bounce a bit too much. If you can run something from the bottom triple as well to firm it up a bit.

-

Power Hungry, Law Disregarder

Yer that's what I thought as well in the middle of designing a moke up out of cardboard and see how that goes then see what good to make the one out of steel or aluminium.

-

Tyre destroying, mad bastard menace

unless you make it out of some decent thickness ally, or it is braced well, the vibrations will work harden it and it'll fatigue (crack) on bends and whatnot. i had that issue when i made one out of 25x3 ally flat bar.

My brackets now are made out of 3mm cnc plasma cut high tensile steel... just cause it's what we had sitting around at work :P

-

Power Hungry, Law Disregarder

I just had a look at one someone else was making and they had problem with aluminium cracking at bends as we'll so looks like it might be steel then.

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

Reply With Quote

Reply With Quote