Nope , any oil that drains into the turbo after shut down will just gravity drain out into the sump, so no catch can needed. When I get home, I'll post a few pictures of my old setup if you like.

Nope , any oil that drains into the turbo after shut down will just gravity drain out into the sump, so no catch can needed. When I get home, I'll post a few pictures of my old setup if you like.

yup yup would be awesome Jack!

bahaha so ive had YOUR pic! i mean the 1st one. the sump is absolutely different to mine but the upper print is the same. i cut mine to make it like yours but i'd have taken yours because mine has the oil cooler bungs located right after the filter therefore i can't use an outboard filter, at least i still can't figure out how to do it, the bloody bungs are on the way

Right oh, its been a bloody long time people, not helped by Microsoft!! Old laptop was XP which worked great but ended up getting completely unusable so know have new (to me) bigger better faster laptop which still has a serial port for tuning the bike. Taken a little while to transfer all my files over, get all my short cuts again, remember all those annoying passwords etc, but i am finally there so business can resume finally.

So, have been busy with work and reno's and weddings (not mine, i have already done that) so have had limited time, but as i last posted in may, i do have some progress to show.

No1 being a bespoke super CNC machined ignition cover, fuck yeah!!!!

Mmmmm no not really but had a little go at making one anyway, so here it is

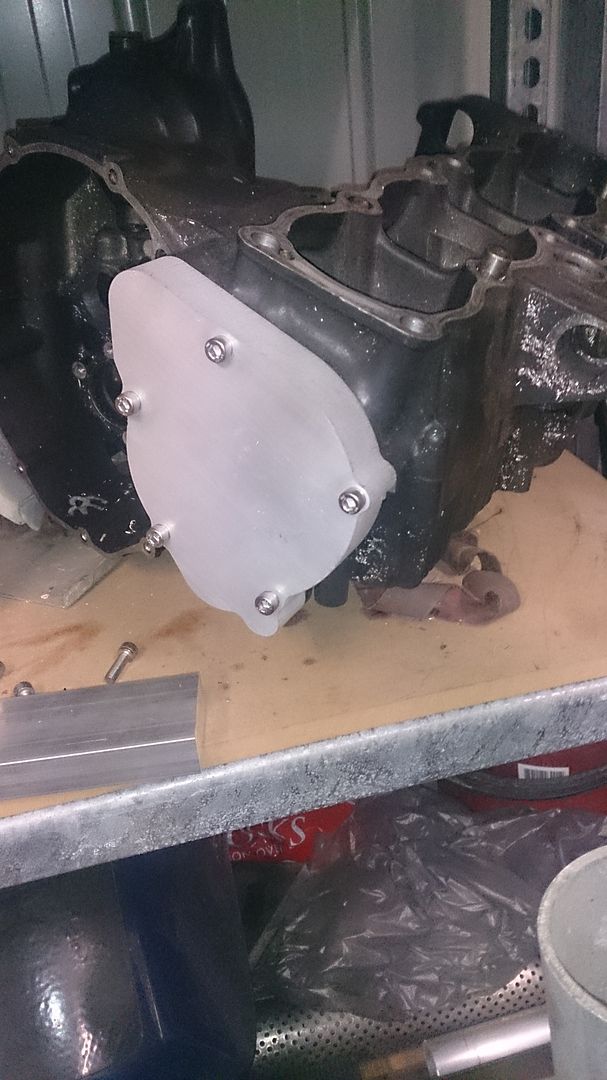

Bit of CAD drawing and i had 2 Waterjet cut 25mm thick alloy blanks

pretty good finnish. a bit like very fine oxy

Got them to just centre mark the holes so took one blank and drilled it out and tried it on my spare cases

Much coolness

Next job was make a new sump for the turbo, the old one was a bit on the small side, had a restrictive pick up position and was always weeping abit where it joined onto the turbo.

So wanted to make a new one with an O ring seal and a solid block drilled through to clamp it on rather than a fabricated system like i had before, so here we go, more pictures

In this one you can see the baffle i put in just in front of the drain hole, so it fill with oil while stationary but hopefully shouldnt surge forward under braking etc. and you can see the cross drilled alloy block with the drain hole

And i ran a cross drilled drain hole at the back with 1/4" BSPT threads in each side so i have options in the future for pumping out of either side but i also wanted to incorporate a site tube with a breather which i figured would also double as an overflow hole, so just incase it trys to fill the turbo with oil, know it should start dripping out the breather hole in the top of the site tube before it starts filling the exhaust. See how it all pans out i suppose but go to be better than what i had.

As stated much coolness

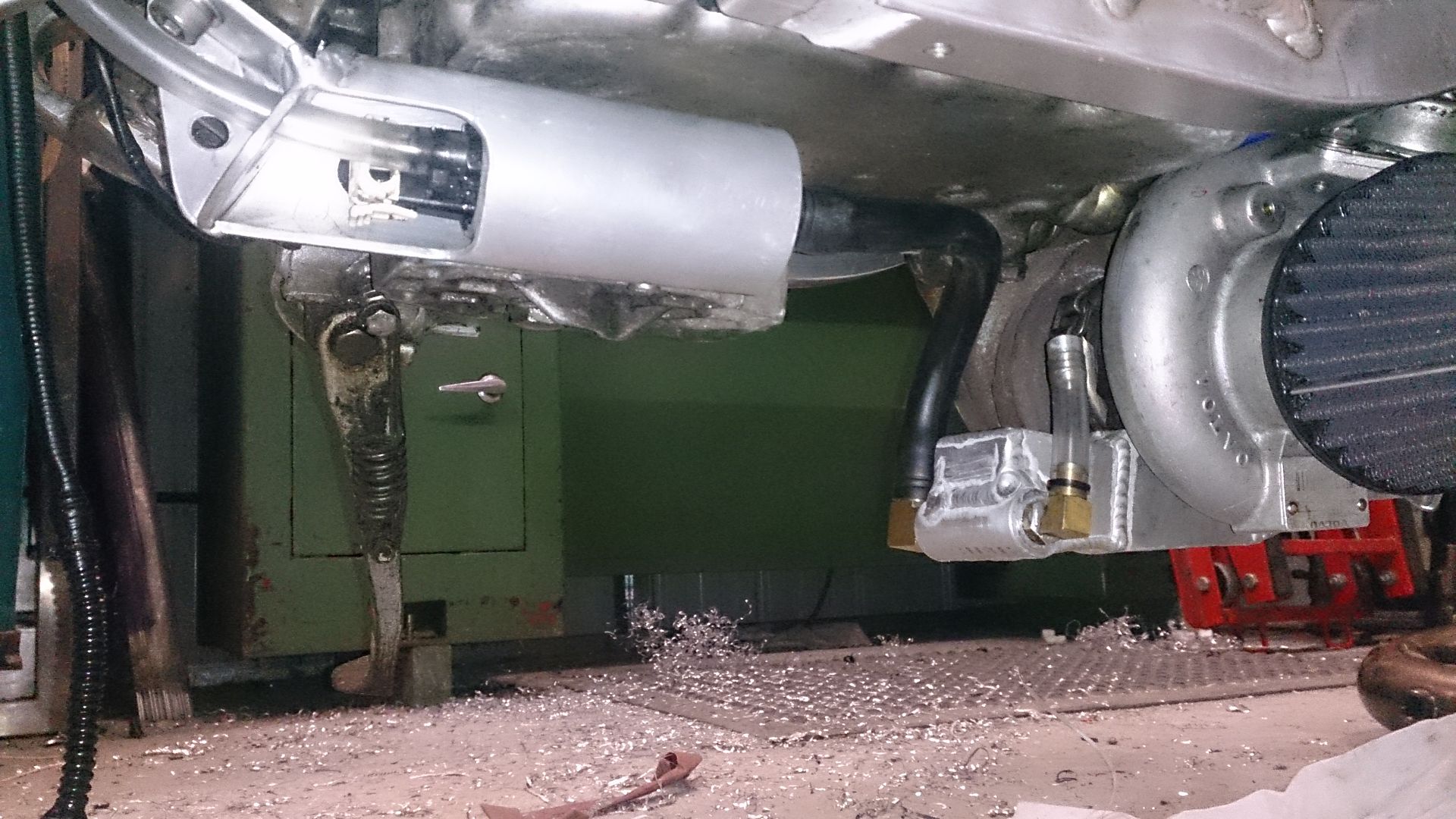

Next, i am still not happy with either of the mechanical scavange pumps i made (and having used my 2 ignition covers to make them, this is one reason i made my own cover haha), so decided to stick with the VDO pump for one last fling. Did some testing and it seems to pump really well and was able to suck oil up a metre of 10mm pipe vertically in about 3 seconds so has plenty of suction as well. So, my old setup had the VDO pump mounted on the turbo sump, but i wanted it more tucked up out the way so made a new mount for it to go with the new sump.

so found a bit of pipe that nearly fitted the pump with some old silicone around it for a cushioned grip, so threw that in the Shun Shin and opened it out so the pump and rubber suround slid in.then cut varoius slots and holes for the wires and pipes and welded on a bit of rod that was drilled and tapped to make a pinch bolt. Then made some plates to bolt onto the centre stand mounts on the slingy frame and drilled some holes in it all for looks.

And then how it all looks together

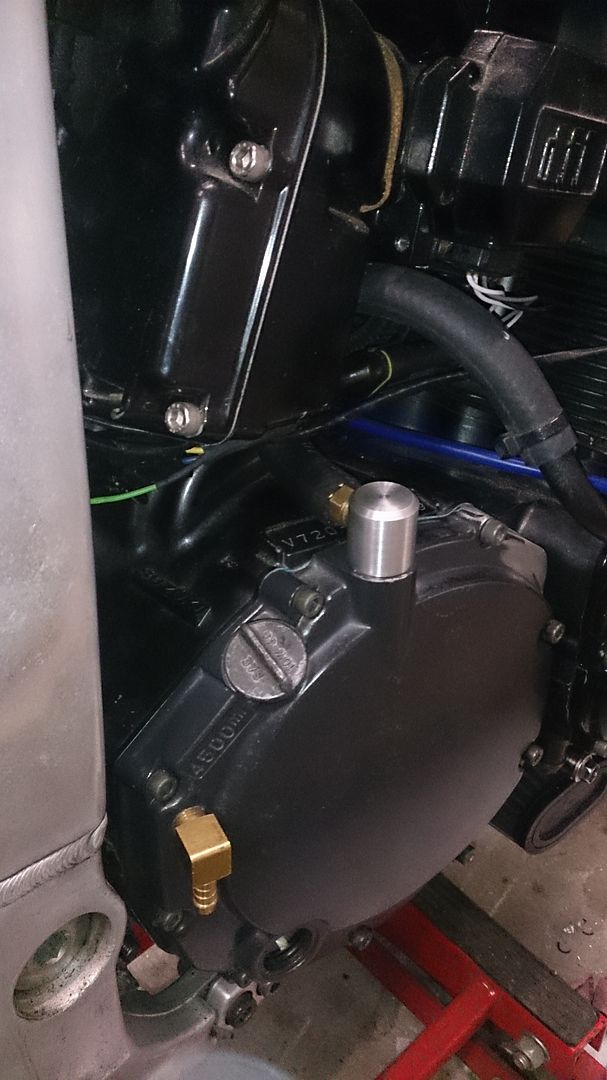

Oh yeah, and nearly forgot, i needed to get the oil back into the engine, and as i already had my old 750 clutch cover with a fitting in it i decided to see if it could be made to fit the bandit engine.....and yes it can . so just punch out the clutch lifting mech, use the grinder and flapper wheel to remove the lump in the middle of the cover and flatten back the internal ribs untill you have clearance over the clutch basket and grind off and clean up the clutch cable bracket. Done, Then you also have a nice point to use as a breather.

So, cover ground out

Fitted

Then make a breather fitting

Its a good tight fit in the cover with the o-ring around it

And i have been gathering parts to replace my fucked forks, so i have some

GSXR750M tripples so they should bolt straight in to the frame,

07 ZX10R fork legs as they bolt into the tripples and are 10mm longer than my existing forks so at least i wont loose any precious ground clearance

95 ZX600F wheel as its spindle matches the width of the M tripples and the diameter of the ZX10 axle holes and has a mechanical speedo drive which i want

13 ZX6 Nissin monoblock radial calipers

Nissin radial master cylinder

And hopefully some 320mm zx9 discs from the very generous Haggar. Bloody Top bloke he is

So just need to find a suitable muddy that i like, make some disc and caliper spacers and some new headlight mounts and we should be in buissiness

All good, most people have no idea just how much and how hard to get right some of this work is

awesome reading as usual Jack, luv watchin you're tryin one way then another one and then all over again, i aint that kind of a perfectionist at all but your options could be very helpful at need

Sick, nice cover.... I reckon it would look even better if you C/B the cap screws so they are nice and flush.

Fuck me, you two (3 if you include Surt) are upping the ante on the shed built custom parts front around here!