Wee bitty this afternoon. Cracked out some scrap cardboard n tape again. Came up with these little curved plates to tie side scoops back to frame so donít look so separate from rest.:-

Flattened out scoop onto biggest sheets of scrap steel I had and couldnít believe it when they fitted plates exactly to edges!:-

You couldnít make that shit up. Lol. Exact size on 4 sides of sheet! Weird.

Chopped out bits with angle grinder, smoothed them off with flap disc then formed the curve round a telephone pole right outside my garage door. Lol:-

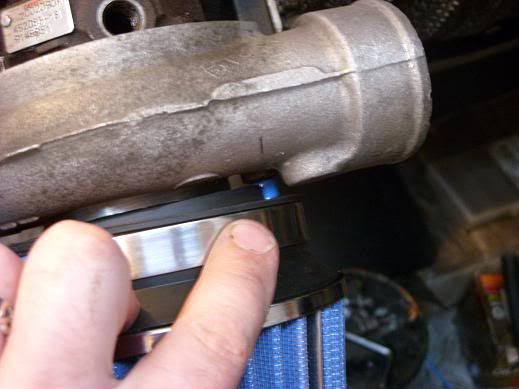

I then welded on some tabs on inside to mount to any handy tabs, etc. Solid as hell once bolted up. Good 1Ē+ clearance from turbo housing too so hopefully keep temps down with airflow through scoops:-

Exact copy of cardboard scoop so looks and sits exactly the same.:-

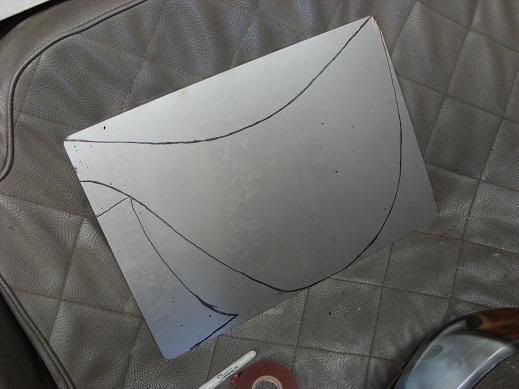

Just need to play about with cardboard template in picture then cut that out n tack onto back so welds hidden. Other end will bolt onto old oil cooler bolt under headstock.

Also came across another old scrap fireguard so thatís my mesh sorted for scoop fronts. Gotta be free! Lol.

Reply With Quote

Reply With Quote